Turbo-gepumpter Sputter- und Carbon-Coater - EMS150V Plus Series

Produktdetails

Beschreibung

The EMS 150V Plus product line is a compact turbomolecular-pumped coating system suitable for Ultra-high resolution SEM and ultra thin-film applications.

The EMS150V Plus product line is available in three formats:

- A ultra-high resolution sputter coater, suitable for oxidizing metals with ultra-fine grian size(EMS150V S Plus)

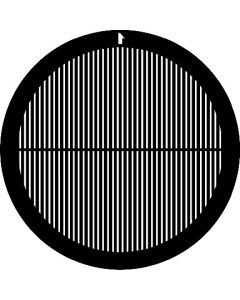

- A ultra-high vacuum carbon coater for TEM applications, e.g. TEM grid coating (EMS150V E Plus)

- A ultra-high resolution sputter coater and ultra-high vacuum carbon evaporator (EMS150V ES Plus). The deposition head inserts can be swapped in

seconds.

Key Features

- Touchscreen control – fully automatic, rapid data input, simple operation

- Multiple, customer defined coating schedules can be stored – ideal for multi-user labs

- Automatic vacuum control, which can be preprogrammed to suit the process and material – no manual needle valve to adjust

- Easy-to-change, drop-in style specimen stages (rotation stage as standard)

- For sputtering of a wide range of oxidizing and non-oxidizing metals – suitable for ultra-high resolution SEM andmany ultra-thin film applications

- Ultra-fine grain sputtering – for advanced high resolution FE-SEM applications

- Vacuum shutdown feature – leaves the process chamber under vacuum when not in use – improved vacuum performance

- Pump hold – allows the system to be held in continuous pumping mode, awaiting user input before continuing the process

- Thick film capabilities – up to 60 minutes sputtering time without breaking vacuum

- Ethernet with local FTP server connection – simple programmer updates

- Three-year warranty

Processes

Sputtering: 0-150mA to a predetermined thickness (with optional FTM) or by the built-in timer. The maximum sputtering time is 60 minutes (without 'breaking' vacuum and with built in rest periods).

Optional accessories for the EMS150V Plus Series:

- Glow discharge (0-80mA operates in DC+ and DC- modes) – for modification of sample surface properties (e.g. hydrophobic to hydrophilic conversion) or for cleaning/removal of contaminating surface residues

- Carbon cord evaporation (optional)

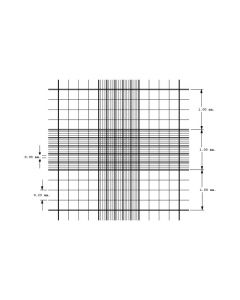

- Film thickness monitor (FTM) - Precise thickness control

- Metal evaporation and aperture cleaning insert – for thermal evaporation of metals from filaments or boats and cleaning of SEM or TEM apertures.

<< For detailed information see datasheet >>

Specifications

|

Display |

115.5mm W x 86.4mm H, 640x480 RGB Touchscreen |

|

Work chamber |

Borosilicate Glass: 150mm ID x 127mm H |

|

Specimen stage |

50mm Ø rotating stage. Rotation speed 8-20 rpm |

|

User interface |

Intuitive full graphical interface with touchscreen buttons, includes features such as reminders for maintenance and a log of the last 1000 coatings. |

|

Sputter target |

Disc style 57mm Ø, 0.3mm thick. Chromium target is fitted as standard. V S and V ES versions only |

|

Safety shield |

Integral polyethylene terephthalate (PET) cylinder |

|

Typical ultimate vacuum |

1 x 10-6 mbar in a clean system after pre-pumping with dry nitrogen gas |

|

Rotary pump |

5m³/h two-stage rotary pump, with vacuum hose, coupling kit and oil mist filter (not included; we recommend the Edwards RV5; see Accessories) |

|

Turbomolecular pump |

Internally-mounted, 70l/s air-cooled turbomolecular pump |

|

Vacuum measurement |

Wide range gauge |

|

Sputter vacuum range |

Between 5x10-3 and 1x10-1 mbar for gold targets |

|

Gases |

Argon sputtering process gas, 99.999% (V S and V ES versions); Nitrogen venting gas (optional) |

|

Electrical supply |

90-250V ~ 50/60 Hz 1400 VA including RV3 rotary pump power. 110/240V voltage selectable |

|

Power factor correction |

Complies with the current legislation (CE Certification) and ensures efficient use of power which means reduced running costs |

<< For detailed information see datasheet >>

Weitere Informationen

| Konformität | CE konform |

|---|---|

| Abmessung | 585mm W x 470mm D x 410mm H (total height with coating head open: 650mm) |

| Verpackungseinheit | 1 Stück |

| Gewicht | 33,4kg |