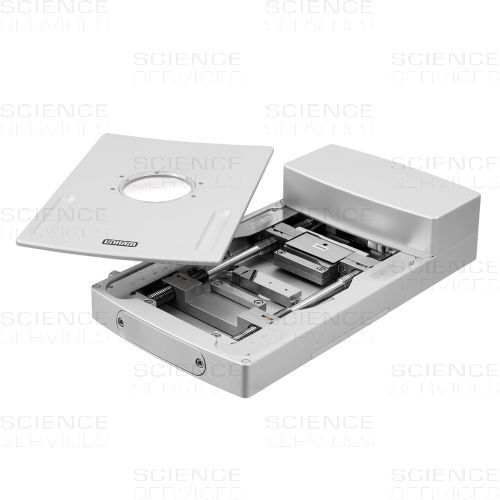

Linkam MFS - Modularer Kraft - und Zugmesstisch

LK11106

Produktdetails

Beschreibung

Die MFS Modular Force Stage bietet Ihnen die Möglichkeit, unterschiedlichste Proben präzise zu charakterisieren und abzubilden. Die detaillierte Analyse thermomechanischer Eigenschaften ist entscheidend für die Entwicklung neuer Materialien, die den Anforderungen in anspruchsvollen Umgebungen, von medizinischen Anwendungen bis ins All, gerecht werden. Die MFS kann im Auflicht und Durchlicht genutzt werden sowie für weitere Analysetechniken wie Röntgen, Raman und FT-IR. Zudem kann die Probenkammer über integrierte Gasanschlüsse gespült werden. Module für die Feuchtigkeitskontrolle und elektrische Sensoren sind optional erhältlich.

Das System besteht aus der MFS-Stage, einem T96-S Temperaturcontroller und der LINK-Software zur PC-Steuerung. Für Anwendungen unter Umgebungstemperatur ist eine LNP96 Flüssigstickstoffpumpe als Option verfügbar.

Hauptfunktionen

Kompressions- und Zugkraftmessung: Testen Sie die Druck- und Zugkraft Ihrer Probe in Abhängigkeit zur Temperatur und erfassen Sie hochauflösende Bilder struktureller Veränderungen.

Zahlreiche Steuerungsparameter: Geschwindigkeit, Verfahrweg und angewandte Kraft können in Abhängigkeit von der Temperatur variiert werden.

Distanzmessung mit Encoder: Ein hochauflösender Encoder gewährleistet eine präzise Messung von Längenänderungen.

Modulares Design: Einfacher Austausch von Probenhaltern, Kraftsensoren und Heizelementen ermöglicht die Anpassung an verschiedenste Probenarten.

Feuchtigkeitskontrolle: Mit der RHGen-Einheit können Sie die relative Luftfeuchtigkeit präzise regulieren.

Individuelle Anpassungen: Kontaktieren Sie uns für maßgeschneiderte Optionen.

Technische Spezifikationen des MFS Modular Force Stage

Distanzauflösung: 0,1 µm

Kraftbereich für Zug- und Drucktests: 0 N bis 2 N, 20 N, 200 N oder 600 N

Kraftauflösung (Maximale Kraft): 1x10⁻⁵ N (2 N), 1x10⁻⁴ N (20 N), 1x10⁻³ N (200 N), 1x10⁻² N (600 N)

Temperaturbereich: -195 °C bis 600 °C *

Temperaturstabilität: < 0,1 °C

Maximaler Verfahrweg: 85 mm

Geschwindigkeitsbereich: 0,1 bis 5000 µm/s *

Bewegungsmodi: Geschwindigkeit, Zug-/Druckschleifen, kontrollierte Kraft

*Abhängig von den gewählten Modulen.

Passen Sie Ihr System individuell an

Die MFS Modular Force Stage von Linkam bietet eine Vielzahl modularer Komponenten, die es Ihnen ermöglicht, das System speziell auf Ihre mechanischen Charakterisierungsversuche anzupassen. Zu den Modulen gehören beheizte und unbeheizte Grundplatten, elektrische Anschlüsse, Feuchtigkeitsoptionen und beheizte Flüssigkeitszellen. Ein breites Spektrum an Kraftmessbalken steht zur Verfügung, darunter ein besonders sensibler 2N-Sensor für Einzelfasern und ein 600N-Sensor für Tests an strukturellen Verbundwerkstoffen. Darüber hinaus gibt es zahlreiche maßgeschneiderte Module und Halteoptionen.

Grafische Daten

Analysieren Sie die mechanischen Eigenschaften Ihrer Proben mit der LINK Software. Kombinieren Sie sie mit dem LINK Imaging-Modul, um Ihre Proben während des gesamten Experiments in situ zu visualisieren. Echtzeitgrafiken werden während des Experiments angezeigt. Sie können Ihre Daten sowohl in Temperatur-Zeit- als auch in Kraft-Weg-Diagrammen darstellen und sie für eine detailliertere Analyse exportieren.

Weitere Informationen

| Verpackungseinheit | 1 Stück |

|---|---|

| Gewicht | 0.000000 |

| Hersteller |

Linkam

|